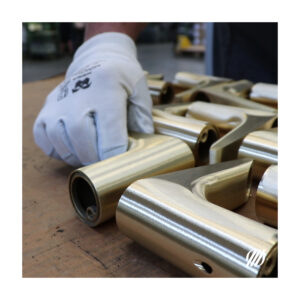

Ottone Meloda has recently expanded its production departments with the introduction of a new automated #polishing system in which the two phases of #granding and #emery are carried out.

Grinding is a completely automated process and is active 24 / 24h which is divided into 6 phases. Abrasive belts of different size and grain work the piece and the operator follows a specific quality control plan. This ensures full compliance with quality standards.

The #emery phase is also completely automated: the piece is finished in detail and at the end, the control takes place on 100% of the production. The latest process is #mirrorfinish thanks to which the piece is first polished by 3 different wheels, and then blown, allowing any residual materials to be removed. Finally, an accurate visual check is carried out thanks to which only the approved

pieces will pass to subsequent processing.

Ottone Meloda has also expanded its production departments in which an automated cleaning system and an entire department for #polishing and #painting have been introduced.

In the painting plant, all the pieces to be painted are placed on the frames where they are cleaned and the internal threaded areas are protected. The operator then proceeds to paint the pieces; the excess paint is sucked from the special booth. The painted frames are repositioned on the trolley and placed in the oven at 190 ° C. After about 30 minutes, the paint is set perfectly. Taken out of the oven, the products rest for about 45 minutes, then the qualitative suitability of each piece is checked and if approved, they will then be assembled and packaged. The liquid painting process is similar to the previous one. This creates transparent, glossy or opaque protective layers. Furthermore, it is used to paint particular materials such as Zamak or Plastic that cannot undergo too high temperatures in the oven.